Services

Cooperage Machinery

If you are a company that views quality barrels as a priority, no doubt you want the strongest, most reliable equipment that you can count on when you need it most. We are very pleased to offer our expertise and industry solutions for your cooperage machinery needs.

Cooperage Machinery Overview

We have taken the current processes of producing cooperage barrels, developed from proven old world techniques, and integrated them into modern machinery processes with the inclusion of PLCs (programmable logic controllers) and HMI touchscreen interface operator controls.

Cooperage Machinery – Manufacturing Experience You Can Trust

pāco manufacturing has decades of experience as a prototype-to-production machine builder for low- to higher-volume applications as well as component parts for complete machines. Explore a detailed look at these cooperage machinery options below:

Innovative Designs for Cooperage Machinery

Our new designs incorporate many improvements for additional precise handling of the product and updated operator ergonomics. These systems are specifically made to boost efficiency and safety with added structural integrity and replaceable tooling to last through decades of production, and they offer operator and maintenance-friendly improvements.

Air Test Station

Features

- Safety Lock & Shut-off

Production Rate

Utility Requirements

Electric: 12 VAC, 1 Phase, 60 Hz, 10 amp

Air: 1” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

Inspection Cradle at Roll-Out

Features

- Guided by conveyor line controller

Production Rate

Utility Requirements

Air: ½” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

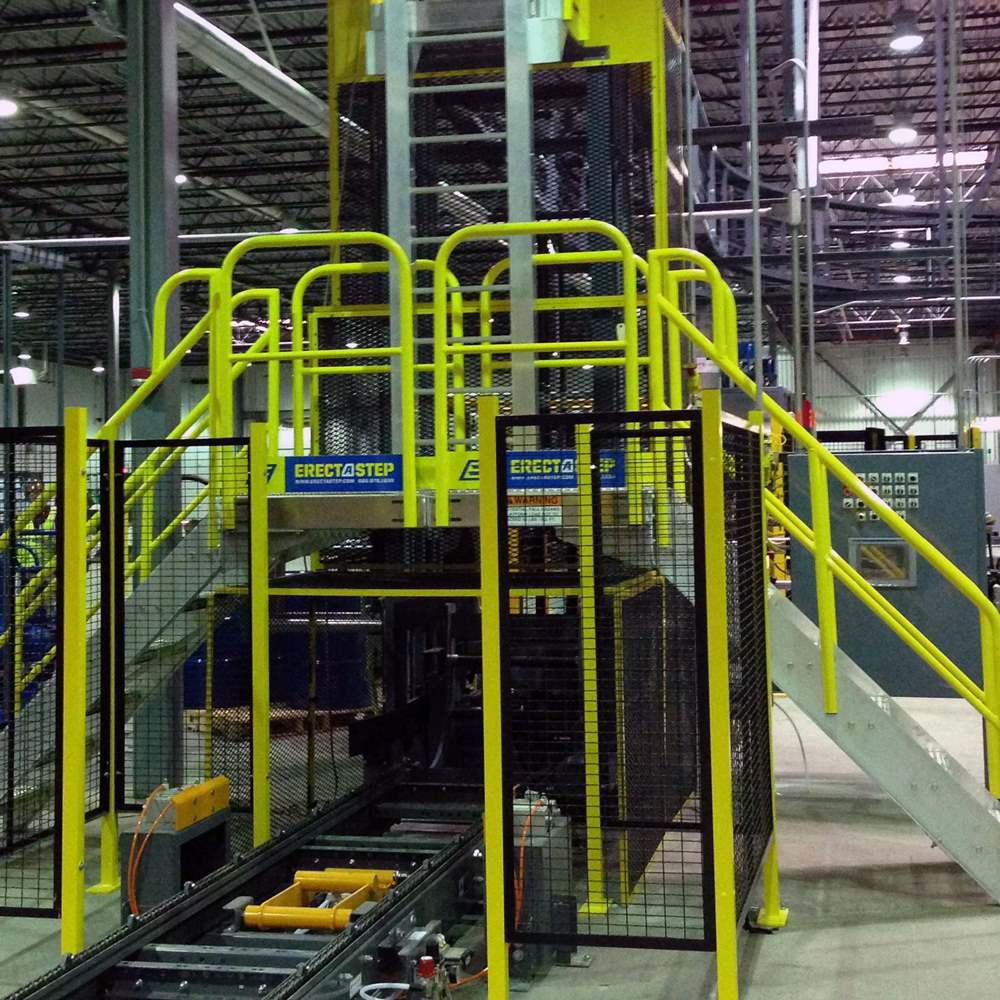

Bilge Hoop Puller Machine

Features

- 30 HP hydraulic power unit

- Infeed barrel centering device

- Perimeter guarding and service platform with skip ladder access (crossover stairway is optional)

Production Rate

Utility Requirements

Electric: 480 VAC, 3 Phase, 60 Hz, 60 Amp

Air: 1” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

- Fill hydraulic power unit with fluid

Air & Water Pressure Test Machine

Features

- Safety Lock & Shutoff

Production Rate

Utility Requirements

Electric: 120 VAC, 1 Phase, 60 Hz, 10 Amp

Air: 1” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

Final Test Inspection Cradle & Drain Pan

Features

- Drain pan for bilge area

- Drain for head area (optional)

Production Rate

Utility Requirements

None

Installation Requirements

- Position, level, and lag unit

- No utilities

Hoop Driver Machine (Hooper)

Features

- 30 HP Hydraulic Power unit

- Safety light curtain

- Perimeter guarding with safety lock access

- Automatic pneumatic barrel infeed (optional)

- Automatic pneumatic barrel lift/

flip/rotate (optional)

Production Rate

Utility Requirements

Electric: 480 VAC, 3 Phase, 60 Hz, 50 Amp

Air: ¾” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

- Fill hydraulic power unit with fluid

Crozier Machine

Features

- Machine guarding with (2) safety interlock access gates

Production Rate

Utility Requirements

Electric: 480 VAC, 3 Phase, 60 Hz, 60 Amp

Air: ¾” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

Head Hoop Puller Machine

Features

- 20 HP Hydraulic power unit

- Infeed barrel centering device

- Perimeter guarding and service platform with skip ladder access (cross over stairway is optional)

Production Rate

Utility Requirements

Electric: 480 VAC, 3 Phase, 60 Hz, 60 Amp

Air: 1” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

- Fill hydraulic power unit with fluid

Bunger Drill Machine

Features

- Bilge Bunger Drill

- Head Bunger Drill (optional)

- Safety Guarding

Production Rate

Utility Requirements

Electric: 480 VAC, 3 Phase, 60 Hz, 60 Amp

Air: ¾” NPT, 90 psig

Installation Requirements

- Position, level, and lag machine

- Connect utilities

Head Press Machine

Features

- Laser head circle guide

- Hydraulic power unit

- Safety Equipment

Production Rate

Utility Requirements

Electric: 480 VAC, 3 Phase, 60 Hz, 30 Amp

Installation Requirements

- Position, level, and lag machine

- Connect utilities

We are your one-stop shop for all your cooperage services! Contact us to find out how we can immediately assist your barreling process with high-efficiency automation equipment.