Services

Contract Machining and Fabrication

Contract Machining and Fabrication: Fixtures and Tooling

Contract machining provides customers with access to the latest equipment and production technologies through our experienced staff of engineers, technicians, programmers, and production personnel. Customers of all industries benefit from our quality management procedures, ensuring consistent and high-quality product, while ultimately reducing operational costs and increasing value.

“Outsource” Your Production Component Machining to Us!

We offer contract machining and manufacturing services to customers across a spectrum of industries. We invite manufacturers to consider our state-of-the-art facilities, advanced equipment, and professional expertise for their production demands.

Allow Us To Be Your Helping Hands!

- Design and fabricate dedicated workholding fixtures

- Individual or multiple product fixturing

- Hydraulic or pneumatic product clamping to suit applications

- Specializing in fixturing for vertical and horizontal CNC machines

Contract Machining

With a vast range of production capabilities and equipment, our dedicated machinists manufacture parts, subassemblies, and machinery to exact specifications.

Our specialty production machine shop handles prototype to medium volume run production, and we offer rapid turnaround times, with emergency and rush services available.

We are experienced with manufacturing parts of all sizes, and our CNC programming and machining capabilities allow for our operation to handle the load and save your company time and effort to dedicate toward other pertinent tasks.

In-house Fixtures and Tooling

pāco manufacturing designs and fabricates dedicated workholding fixtures for our manufacturing customers, as well as fabricated CNC fixtures and tooling based on our customers’ precise requirements.

Our skilled toolmaking team provides special tooling and fixtures for a wide range of applications, and we are well-versed in the manufacture of dies, jigs, and fixtures of various sizes.

All of our products and processes are held to the highest industry standards, with multiple levels of thorough tests for quality and accuracy prior to shipment.

Additional Benefits of Contract Machining and Fabrication

Contract Machining Advantages: Cost Savings

When outsourcing your machining projects to pāco, you experience lower manpower requirements because we employ an entire team dedicated to optimizing the machining process. Ultimately, this allows our team to provide customers with fixed-cost predictability.

Contract Machining Advantages: Space Savings

When investing in contract machining you do not have to worry about floor space requirements and overhead necessary for specialized machinery used for these projects. Allow pāco to machine your parts and manage your inventory—the benefits are instantaneous!

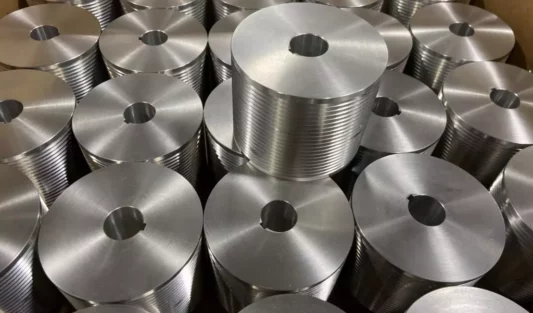

Poly-V Pulleys

Look To Us For Your Special Orders!

In addition to machine shop services, pāco manufacturing provides poly-v pulleys that will keep your operation running smoothly. pāco manufacturing provides our customers with single units and short-run productions for non-standard special poly-v pulley orders. Our expertise with “L-section” and “J-section” belt profiles sets us apart in the industry and allows us to uniquely meet the needs of countless customers.

Our Size Range and Materials

The size range we offer is up to 10″ diameter and 10″ length. Additional varieties and variations will be considered on a case-by-case basis. Typical materials of construction are aluminum, mild steel, and stainless steel. Finishes such as anodizing and hard-coat anodizing are available.

Look no further if streamlining production is an initiative. Think of our contract machining resources as an extension of your own capabilities!